Model Number:Consumer electronics FPC

Type:FPC

Place of Origin:Guangdong, China

Base Material:Polyimild

Copper Thickness:0.4-2mil(10-50um)

Board Thickness:0.2-6mm

Min. Hole Size:0.1mm(4mil)for HDI / 0.15mm(6mil)

Min. Line Width:0.075mm/0.075mm(3mil/3mil)

Min. Line Spacing:0.003''

Surface Finishing:HASL/OSP/Ag/ENIG/ENEPIG/Immersion silver/Tin

Board Size:Custom

Layer No.:1-8 Layers

PCB Test:Flying probe and AOI (Default)/Fixture Test Base, Cover film, Stiffeners thickness:

0.5mil, 1.0mil, 2.0mil, 3.0mil, 4.0mil, 5.0mil, 6.0mil,0.10um

BGA Ball Pitch:1mm ~ 3mm(4mil ~ 12mil)

PCB Assembly Method:SMT, Through-hole, Mixed, BGA

PCB Assembly Test:Visual Inspection (default), AOI, FCT, X-RAY

Electrical Testing:

Net List Test, Flying Probe Test, Through Hole Test, Dual Access Test

Certificate Standard:IPC-A-600H Class 2, Class 3, TS16949,ROHS and as your need

Special requirements:Buried and blind vias, Impedance control, via plug

1.Introduction of Flexible PCB Cable PCB

This is a type of polyimide PCB for the application of cable. It’s a single sided layer board at 0.1mm thick. The base laminate is from ITEQ, Solder mask and silkscreen from Taiyo. It’s fabricated per IPC 6012 Class 2 using supplied Gerber data.

Linghangda Circuits is capable of providing full turnkey and partial turnkey printed circuit board assembly services. For full turnkey, we take care of the entire process, including preparation of Printed Circuit Boards, procurement of components, online order tracking, continuous monitoring of quality and final assembly. Whereas for partial turnkey, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

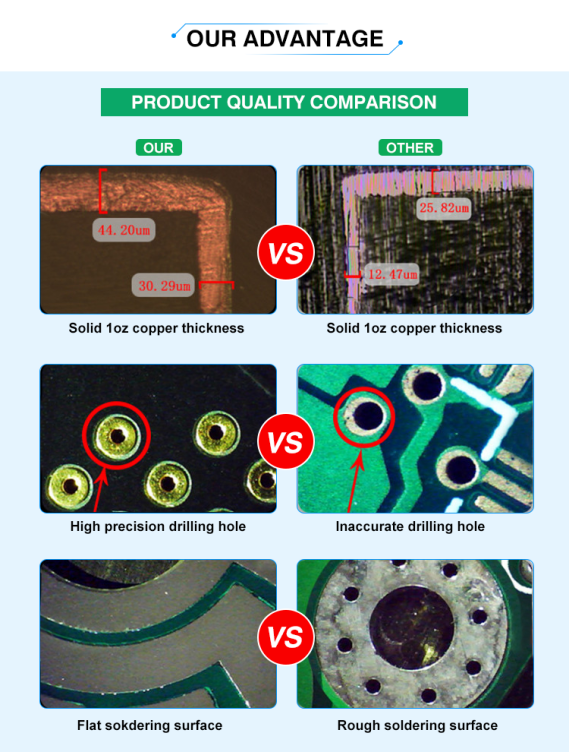

2.Features-Our Products Advantage

1. Over 10 years experience manufacturer in PCB Assemble and PCB field.

2. Big scale of producing makes sure that your purchase cost is lower.

3. Advanced production line guarantees stable quality and long life span.

4. Produce almost any PCB as your requirement.

5. 100% test for all customized PCB products.

6. One-stop Service ,we can help to purchase the components.

3.Standard Flex Materials:

Polyimide (Kapton) 0.5 mil to 5 mils (.012mm - .127mm)

Adhesiveless Copper Clad Base Material 1 mil to 5 mils

Flame Retardant Laminate, Base Material, and Coverlay

High Performance Epoxy Laminate and Prepreg

High Performance Polyimide Laminate and Prepreg

UL and RoHS Compliant Material on request

High Tg FR4 (170+ Tg), Polyimide (260+ Tg)

Base Copper:

1/3 oz. - .00047 in. (.012mm)–rarely used

1/2 oz. - .0007 in. (.018mm)

1 oz. - .0014 in. (.036mm)

2 oz. - .0028 in. (.071mm)

Solder Mask: Customized

Polyimide Coverlay: 0.5 mil to 5 mils Kapton (.012mm - .127mm)

with 0.5 to 2 mil Adhesive (.012mm - .051mm)

LPI and LDI Flexible Soldermasks

4.Flex PCB Capability

5.Flex PCB Display